How it's made

From an Art Proof

The production process begins with an art proof. New artwork or any modification to the artwork will require a new die/film at additional cost. Proofs are mainly used to verify imprint accuracy and are presented in black and white. Colour proofs are intended for Silk-screening imprints with multiple colours and custom PMS colours. Colours may vary from monitor to monitor and we suggest to view PMS colours on actual Pantone Solid Coated Formula Guide (if available).

Creating a Stamping Die(s) or Films

Once the art proof is approved, a stamping die or film is created.

Hot stamp or Deboss/emboss die

A stamping die is a magnesium and zinc plate that has a negative raised impression of te imprint. A deboss or emboss die is a thicker metal plate with a deeper impression. Imprint will be 100% size as per the art proof.

Film

An imprint is placed on a digital file with the exact dimensions of the sealing die (sealing die is what makes the product.) The digital file is then made into a negative image. The film is subsequently processed using a film processor to create a black & white film.

Making The Product

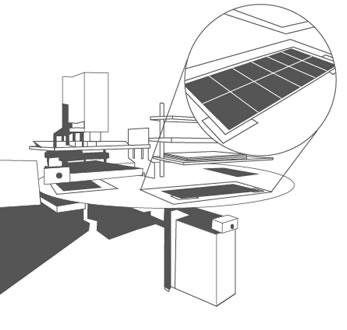

The sealing department is responsible for manufacturing the vinyl products. The raw materials (comprised of vinyl sheets, cardboard and/or foam inserts) are assembled in layers on a turntable. Using a sealing die, radio frequency waves and heat is applied to the sealing die which simultaneously cuts and seals to create the product.

The sealing die (show below) consists of a cutting blade, sealing brass, foam padding, mounted on wood board. This is a example of a 2-UP sealing die.

Step 1: All products are assembled in layers. Customers have the option to customize the product. The sealing die cannot be modified; however, the product can be customized in many ways:

- Substituting vinyl types

- Foam padding

- Vertical or Horizontal pockets

- Business card pockets

Step 2: The sealing machine’s hydraulic plate presses the mounted sealing die on the layers of material. Using heat and radio frequency, the cutting blade and sealing brass seals and cuts the PVC.

Step 3: The sealed product’s excess material is then manually stripped. The scrap material is recycled.

All custom sealing & cutting dies are the property of HYLINE Dateminder Inc.

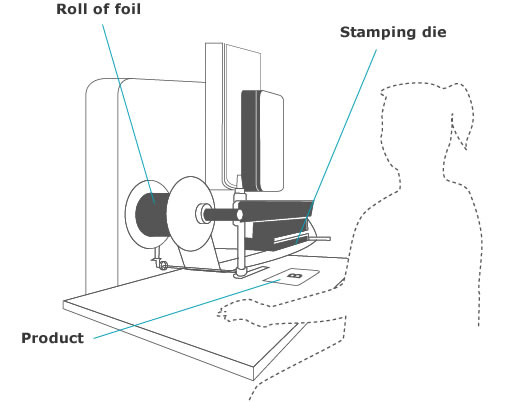

Hot Stamp imprinting

Hot stamping uses a magnesium and zinc metal stamping die, foil, heat and pressure to create the imprint. The pneumatic machine presses the heated stamping die onto the foil and product thereby creating a foil stamped imprint.

Deboss or Emboss imprinting

Debossing is a depressed imprint and Embossing is a raised imprint. These imprinting methods are best suited for look of luxury vinyl and create a distinguished look.

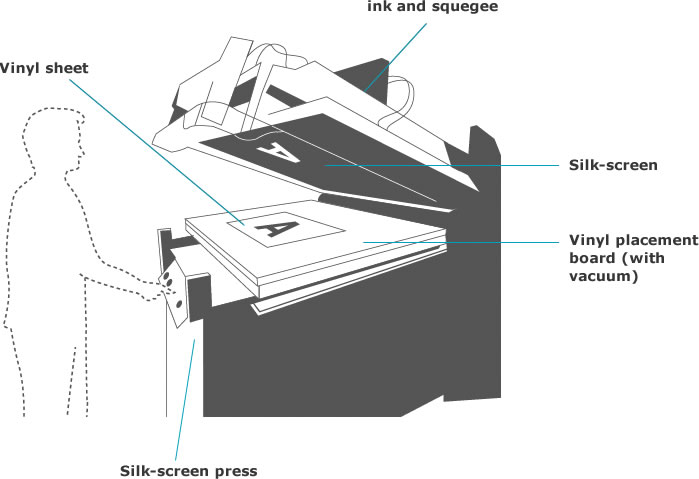

Silk-screen imprinting

Silk-screening is a process where ink passes through a mesh screen and onto to the vinyl sheet. Silk-screening is a lengthy and costly process as compared with hot stamping.

Step 1: A black and white film is produced.

Step 2: A screen is coated with a chemical that is attractive to light.

Step 3: The film is superimposed to the coated screen.

Step 4: The screen and film combination is then exposed to a ray of strong UV light whereby the exposed coating stays on the screen when washed.

Step 5: The silk screen is washed.

Step 6: Ink is mixed to the specified PMS pantone.

Step 7: The screen is placed on the silk-screening press.

Step 8: Ink is placed on the top of the screen.

Step 9: The automated machine is ready to apply ink to the screen and onto the vinyl sheets.

Step 10: The vinyl sheets are screened per colour one sheet at a time. The automated machine has pinhole size holes on the placement board where a vacuum stabilizes the vinyl sheets when the ink is being applied by the squegee.

Step 11: The product is air dried (for conventional ink) or cured using UV light (for UV inks).

Step 12: The cured imprinted sheets are then sent to the sealing department to manufacturing the product.

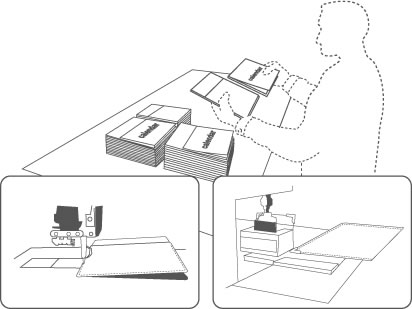

Fulfillment

The finishing department will add the finishing touches such as the following:

- Inserting calendar inserts

- Detailed stitching

- Adding metal corners

- Adding clips for clipboards

- Riveting binder rings

- Inserting binder clips

- Packing

Shipping

All products are safely packaged in corrugated boxes. We ship by ground or air, or orders may simply be picked up at our location.